A Biased View of Casters Supplier

Wiki Article

The 2-Minute Rule for Casters Supplier

Table of ContentsNot known Incorrect Statements About Casters Supplier Casters Factory Fundamentals ExplainedIndicators on Casters Supplier You Should KnowExamine This Report on Casters Factory

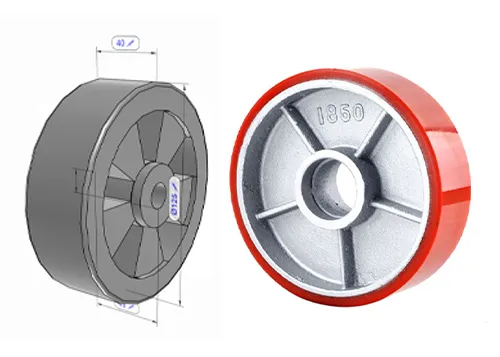

Selection as well as usage of top quality bit canisters is indispensable for the production of fine yarns. Leading mills across the globe recognize this and also that's exactly why the need for tailor-maked HDPE is rising significantly. Given that the capability guarantee of these canisters are originated from its components, purchasers are increasingly looking for suppliers that provide end-to-end bit dealing with services.In contrast to what lots of believed previously, wheels are much more than just wheels. Specialist caster wheels for rotating cans include the install along with the wheel itself and they make certain smooth sliver transportation (and quality stability) in the mill floorings. Wheels with various physical specifications (sizes, shapes, etc) are offered for the different kinds of bit canisters utilized in the rotating process.

The casters you choose require to have the integrated capability to meet the exact demands. Some typically made use of caster wheel products are: Wheel wheels made with polypropylene are ergonomically designed, and also have superb resistance buildings. Consequently, they are widely utilized in locations that are subjected to wetness, chemical solvents and also various other possibly corrosive product - casters supplier.

In addition, the material can additionally function in rough exterior problems, and also is not influenced by solvents either. Casters created with ductile iron or actors iron enhance the loading ability of the object they are fitted with. They are temperature-resistant also, provide smooth movement, and also are not most likely to obtain damaged or cracked frequently.

Little Known Facts About Casters Supplier.

, like Jumac Cans, normally have both Nylon 6 and also polypropylene wheels (with zinc-coated bodies) in their profile. Caster wheels are likewise categorized on the basis of their toughness rankings, which shows their tons abilities. On this basis, wheels can generally be separated under three heads: These can normally support weights over of 140 kgs, with no considerable movement or mechanical troubles - casters supplier.

Weights in the array between 70 kgs and 140 kgs can be mounted on medium-duty wheels. Before really putting on the lots, it is always suggested to cross-check the wheel abilities with the producer. As their name recommends, these wheels include the most affordable load-bearing capability (usually, under 70 kgs).

The wheel wheels have actually restricted ability to move, contrasted to rotate wheels. The fixed wheels can just be rolled in reverse and forward and also as such, are not suitable for particular applications.

Caster China for Beginners

While kingpinless casters are usually a lot more costly than normal swivel wheels, their shock-absorption as well as stress-resistance capabilities are significantly higher. A particular kind of caster wheel (that have to be fluff and dust-free) are required for HDPE rotating cans. Other industrial wheels require certain various other wheel options. Wheel wheels are readily available in caster manufacturer the list below types: These wheels are made by systematic application of stress and heat to glass/paper layers.These tracks have great traction, as well as they can be used with equivalent simplicity on both floor surface areas and tracks. The high shock-absorption capability of pneumatically-driven wheels is stemmed from the air completed them. These wheels are offered in both tubeless and also tubed varieties. There are a number of ranges (e.

Generally of thumb, steel wheels are the hardest of them all complied with by the plastic wheels, and finally, the rubber casters. The firmness or soft qualities of wheel wheels directly affect their motions. Typically, the tougher the wheel is, the lower is their 'rolling resistance'. This, consequently, guarantees that relocating the casters at an uniform rate calls for much less pressure.

Therefore, softer wheels can function a lot more 'quietly' than their more difficult counterparts. The size and also size of caster wheels also need to be examined specifically when they are being fitted to rotating canisters for smoother bit handling. Both the 'starting resistance' and 'rolling resistance' figures are vice versa proportional with the wheel size and also width.

Casters Supplier Things To Know Before You Get This

Due focus requires to be paid to the stability factor. Offered the significance of wheel install on the overall capability and resilience of the product, a category can be done on its basis - caster wheel manufacturer. Stem install, plate mount as well as bolt-hole place (stemless selection) are the usual sorts of installs used.Buyers likewise require to inspect the measurements of the wheel stem, or ask the producer concerning the same. Not all caster wheels have comparable sets of attributes.

Casters can likewise be twin-wheeled in the housing. Depending on the underlying applications, the wheel setup varies as well (for both swivel casters as well as inflexible wheels).

Report this wiki page